Smart Manufacturing

Intelligent Automation

Smart Factory Boosts The Productivity of Automation

The concept of Industry 4.0 is considered a smart factory that integrates the applications throughout the hardware, software, and system. As the ICT industry reaches maturity, intelligent manufacturing is coming to reality.

Smart Manufacturing stands for making information in manufacturing readily available and visible.

Since digitization & visualization initiated steps toward automation, such as putting systems like SCADA and components like PLCs & HMIs together, a huge progression of industrial automation began. (How do SCADA, PLC, and HMI work together?) As computer technologies evolve from IIoT and edge computing, Big Data brings real-time decision making and machine learning to reality.

Another development in automation & visualization is Automated Optical Inspection (AOI) system. It also help to accurately detect defects and improve the quality or speed of production.

How Smart Manufacturing Can Benefit from IoT in Industry 4.0

When it comes to the application of smart factories and the Internet of Things (IoT) in Industry 4.0, we can observe several key areas benefiting. Firstly, the scope of IoT applications includes monitoring and diagnostics, remote monitoring and control, asset tracking, production data analysis, energy efficiency optimization, safety monitoring, and more, all contributing to improving manufacturing efficiency and intelligence.

Benefits In Precision Manufacturing

Precision Manufacturing benefits from more intelligent automation significantly. It tremendously improves the precision and accuracy of part fabrication. The 2023 TIMTOS EXPO shows how Industry 4.0 technologies were deployed from CNC machines to the whole factory management. Besides increasing efficiency and effectiveness in operations, smart manufacturing also helps the shop floor prevent downtime and reduce waste.

Solutions For Smart Factory, Automation, & CNC Machine

Netiotek provides a series of solutions for different sections of intelligent manufacturing, from smart production lines, and automation systems to CNC machine controllers, Visit to select your best fit.

Smart Production Line

Production line automation made the manufacturing cycle time shortened, bottleneck costs reduce, energy & resources save, and quality improve. Industry 4.0 advanced it as Smart Production Line with new technologies such as 5G, Artificial Intelligence (AI)

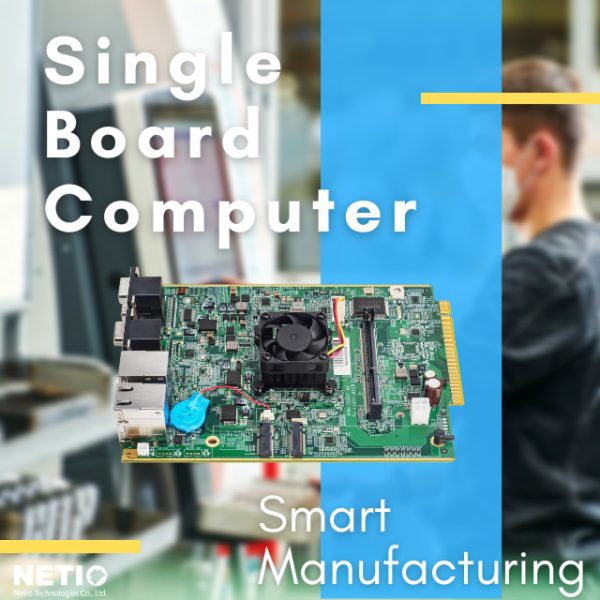

Single Board Computer

SBCs are completely computers built onto a single circuit board. They typically include a processor, memory, storage, and input/output (I/O) capabilities.

DIN-Rail Computer

NEDPRC Series is designed with the latest Elkhart Lake processor which can connect with a range of devices through different built-in IO ports.

Rugged Computer

A rugged PC, compare with a consumer PC, which is more suitable for harsh environments with 24/7 operation.

Panel PC|HMI

Industrial HMI & Panel PC. Netiotek partners with FATEK, a great Taiwan automation company to provide a wide range of HMI products.

Enable Seamless Edge-to-Cloud Connection

———— Collect, Connect, Control, All-in-one ————

Edge IoT Gateway

An ultimate bridge between Iot devices or servers

Netiotek’s NEDRPC-6412A is an industrial grade DIN-Rail computer that integrated OT products with IT & Cloud Platform communications. With a ready-to-use & customnizable software, it realizes data collection, device conncetivity, and remote control. This IoT Gateway benefits IoT developers and system integrators with flexibility, compatibility, and cost-effectiveness.

What benefits can Industry 4.0 create in the automation of precision manufacturing ?

White Paper

We shared how to deploy a Smart Production Line.

Download FREE whitepaper to get knowing the solution for staying ahead of the competition!

Netio Technologies

Your Best Design Partner !