There are a lot of machines performing many tasks automatically in many industries. Monitoring errors during the workflow and taking actions when an emergency occurs is crucial for maintaining stable operations.

Sometimes, operators may not identify the problems of the machine or system by visual observations. An alarm system can solve this problem and improve efficiency. Nowadays, a PLC-based alarm system is common in mass automatic machines industries.

Alarm systems are also helpful to detect emergencies in different applications. PLC-based system is an economic and quick adopted design. The advantages of Programmable Logic Controller (PLC) are simply wiring, processing fast, conveniently operating, and high reliability.

Related Reading:

Which one is better? The best controller choice for your application

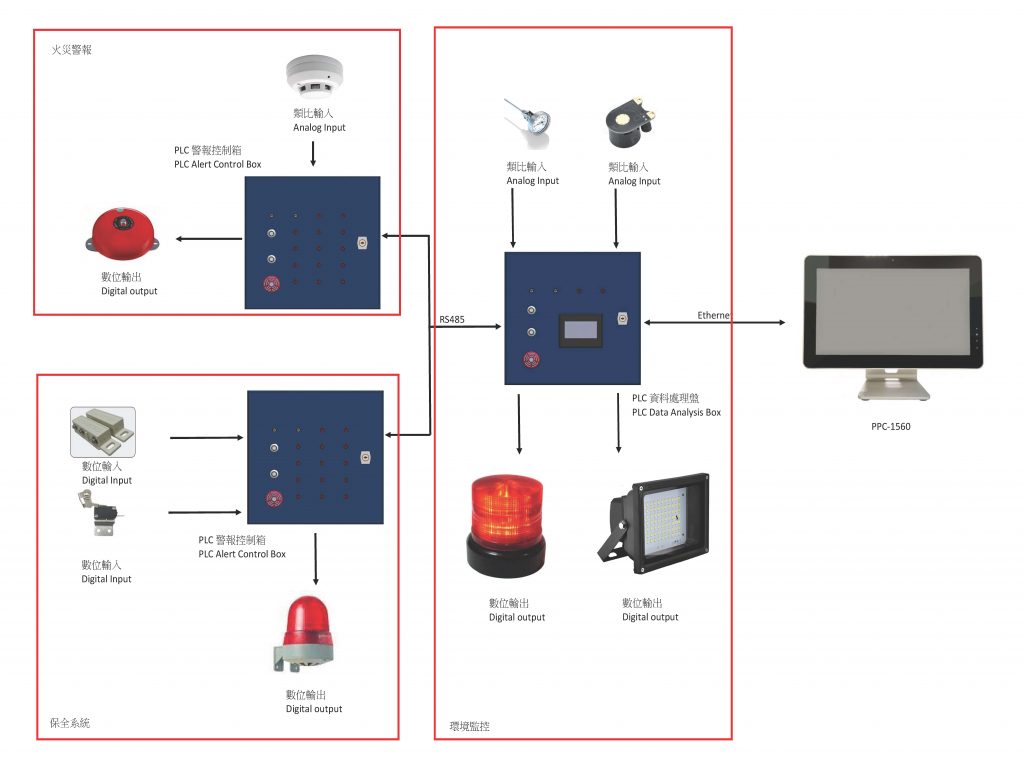

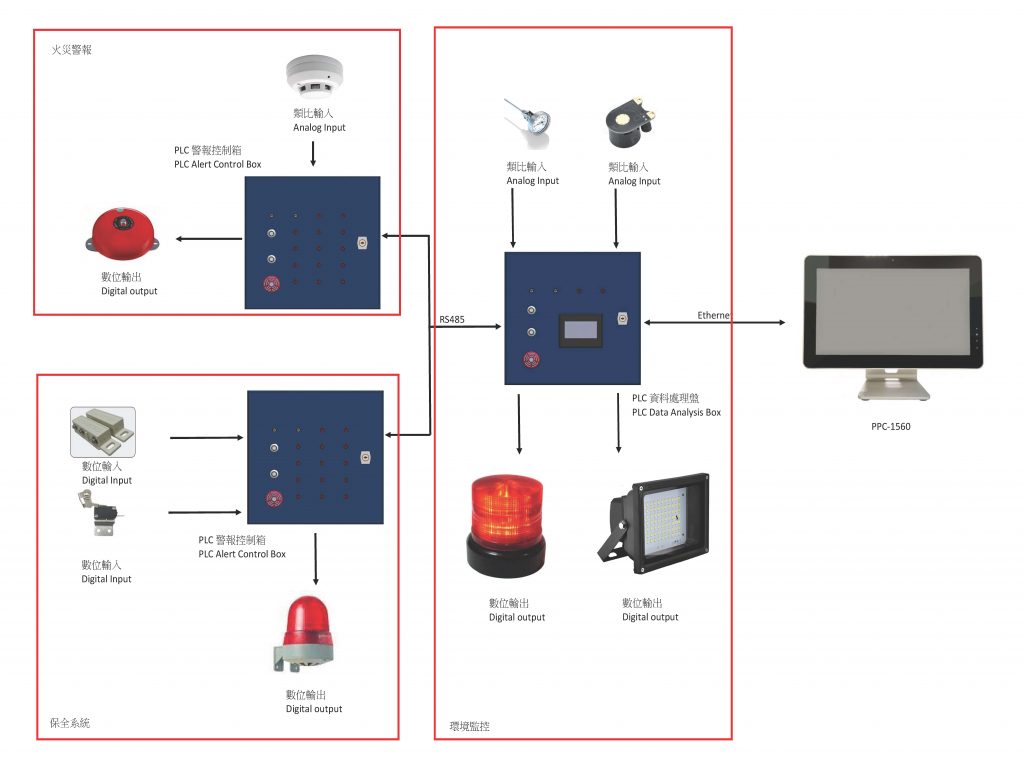

The purpose of an alarm system is to let users and the appropriate authorities know whenever there is an emergency. The detections of emergencies include security, temperature, and fire, etc. The alarm system identifies these emergencies by sensors setting on the control points. When the sensor received abnormal data, it immediately responded to inform related members. Meanwhile, the control room also can decide on the emergency by a systematic information analysis. It helps when the alarm system is implemented on a large scale of the environment.

Alarm systems work by sensors sending out signals to a central monitoring station when detected something faulted. The central hub of an alarm system is mainly designed as a panel (HMI), so the users and the appropriate authorities can get immediate readable data or information of the situation. At the same time, the alarm system needs to respond based on the programming setting and send out an alarm.

When it comes to deciding which kind of controller is the best fit for the system, there is no doubt that a Programmable Logic Controller (PLC) system is your first choice. You only need PLC and the monolithic integrated circuit to complete the alarm tasks.

Related Reading:

Marine Integrated Bridge System (IBS) | EN60945, IACS E10 Certified Touch Screen & Panel PC

Combining with a big picture of how alarm systems work, we wanted to discuss further the design of a PLC-based ship alarm system.

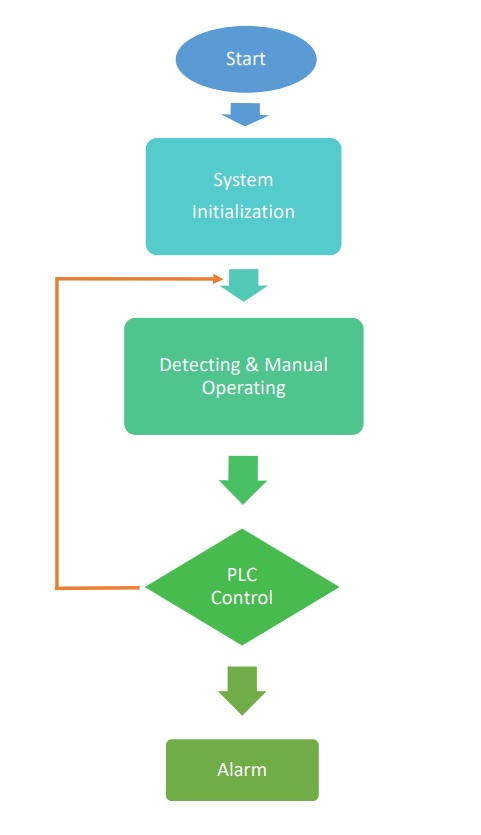

PLC-based Alarm System Operating Diagram

When an issue or danger is detected, detectors(sensors) transmit measurement signals to the PLC control terminal (the central hub of an alarm system). Members on the ship can also send signals manually. The PLC will issue control instructions by analyzing operations, which include the sound and light alarms.

Alarm System Hardware Design

The hardware design is an important component of the alarm control system. It needs to include detectors such as temperature, smoke, fire, and light sensors. And the alarm devices like ring bells and warning lamps. It also has to include some visual displays so the users or authorities on the ship can get more information about the issue.

Alarm System Software Design

A well-organized design of the software is the critical value. To design the software means to correspond all points that need to be controlled. A naming table of control points is necessary for identifying how the control points are connected to the PLC I/O interface terminals. So, the signals can be transmitted and recognized correctly.

In the following articles, we will share our success stories on different applications.

Welcome to visit our solutions for related applications.

Healthcare

Intelligent Transportation

I Factory / Manufacturing

Industrial & Telecom Servers

Marine

Fanless

Thank you

Greetings! Very helpful advice within this post! Its the little changes that produce the greatest changes. Thanks for sharing!

Thank you!

Hm,.. amazing post ,.. just keep the good work on!

Thank you

Top ,.. I will save your website !

Thank you

Top site ,.. amazaing post ! Just keep the work on !

Thank you