Taipei Internationl Machine Tool Show (TIMTOS)

It's opening!!

Location

Nangang Exhibition Center, Halls 1 & 2, and TWTC Hall 1

Date

2023 / 3/6 ~ 3/11

Taipei Internationl Machine Tool Show (TIMTOS)

Taipei International Machine Tool Show, also known as TIMTOS, will return in 2023 from March 6 to 11 at Nangang Exhibition Center, Halls 1 & 2, and TWTC Hall 1. With around 6,100 booths for over 1,000 exhibitors, this will be the largest trade show ever since Taiwan lifted all its border controls during the COVID-19 outbreak.

Big brands in the Machine Tool ecosystem from 17 countries/regions including HIWIN, PMI, YLM, SHINBU, KAFO, CHMER, Hartford, SOCO, YOU JI, TAKISAWA, YCM, Kao Ming, Victor Taichung, Delta, Siemens, HEIDENHAIN, TRUMPF, FANUC, igus, MAZAK, Mitsubishi, THK, Zeiss, Universal Robot, Mitutoyo, Keyence, and Renishaw are going to showcase the latest models and smart solutions. Meanwhile, U.S., Germany, Switzerland, and Denmark will also exhibit their comprehensive supply chains as pavilions.

What’s more, the show will debut three new themed areas featuring “Advanced Metalworking Technology,” “Additive Manufacturing” and “Future Manufacturing.” It provides participants with a thorough understanding of whether the mature metal manufacturing ecosystem or intelligent development for smart production.

Even though the tension between U.S. & China, the war between Ukraine & Russia, and inflation is impacting the economy, from the stats of participants, there are still huge opportunities that might be the same as before the pandemic.

Netiotek dedicates itself to being the best computer hardware provider in smart manufacturing. We join this big event and share our insights and trends online.

It's Opening!

Taipei, March 6, 2023: The Taipei International Machine Tool Show 2023, also known as TIMTOS, kicks off today. The physical mega show will go for six days till March 11.

The opening ceremony saw distinguished guests, including President Tsai Ing-Wen, Vice Premier Wen-Tsan Cheng, Director Sandra Oudkirk of American Institute in Taiwan, Taipei Office, and the organizers TAITRA and TAMI, giving remarks and congratulations on TIMTOS 2023.

“TIMTOS 2023 is starting a new chapter for the global machine tool community after the COVID-19 pandemic,” said TAITRA Chairman James Huang. Huang expressed excitement about the dynamic return of international attendees, including four national pavilions (USA, Switzerland, Germany and Denmark) and delegations led by the industry associations in India, Malaysia, Thailand, Vietnam, Japan and Turkey. Huang also pointed out that this year’s TIMTOS highlights the ESG trends and their impacts on the machine tool industry’s transition toward making manufacturing more efficient, smarter and more sustainable. TAMI Chairman Larry Wei also gave a warm welcome to the international visitors reunited at TIMTOS 2023.

Maker Workshop Part I -

The Key to Intelligent Manufacturing in Metalworking

On the first day of visiting the exhibition, Netiotek attended the activity of “Maker Workshop Part I – The Key to Intelligent Manufacturing in Metalworking”.

KuenLin Precision shared the application of digital intelligent stamping: through single-arm mechanical rapid material feeding/changing technology, and new technologies such as visual positioning to replace traditional. A single production line can produce a variety of products and meet the ability to customize orders.

Smart mold monitoring: applying the concept of face recognition, through external sensors plus AI computer equipment, mold prevention strategy can be addressed by waveform comparison or stamping signal comparison. It improves production efficiency and quality. Digitization of tool molds also contributes to machine learning and intelligent applications.

Taiwan Asahi Diamond Industrial Co., Ltd. introduced the application of diamond tools using in the electric vehicle manufacturing. The main three parts of EV, electrics, electronics, and controls can all be made by diamond tools. By deploying water-soluble cutting fluid can also accomplish ESG and environmental sustainability.

The Taiwan Sheet Metal Management Association is the spotlight of today’s workshop. Even though the association is still relatively young since its establishment, it dedicates great importance to the connection between industry, government, academia and research. The association is committed to refreshing the stereotype of the sheet metal industry. Members of the association are invited to guide how companies implement AI for making industrial environment intelligent, and how to pursues innovation, and to be friendly to employees.

The MIRDC shared the additive manufacturing technology. There are seven major methods of additive manufacturing and they also show the practices of these methods through videos. Designs that are difficult to demould, or the processing of complex components can be overcome through additive technologies. Some companies already benefited from the advances.

【Forum】Future Manufacturing

On the second day of the exhibition, we participated in the “Future Manufacturing Trends Forum”. Secretary of the International Trade Bureau of the Ministry of Economic Affairs said that in response to the transformation of manufacturing technology, the government has also actively provided a series of support to the industry this year: including providing training, assisting in net carbon emission reduction, and subsidizing utilities and the environment. Hope to promote industrial transformation. The Deputy Secretary of the Trade Association also said that the digitization and intelligence of machinery is not an easy road. However, the COVID-19 epidemic and the accident of supply chain disruption caused it to become in vogue. Therefore, this machine tool exhibition holds the “Future Manufacturing Theme”, hoping to discuss and exchange related technologies such as the digitalization of production lines, digital twins, and the industrial metaverse.

Siemens

Green Transformation

Aditya Ramkrishna, general manager of Siemens Digital Economics Industry, shared the green transformation of the machine tool industry and how to lead the industry’s international competitiveness. The machine tool manufacturing industry always got its stereotype of “dirty industry”. Because of this, it is necessary to invest more in ESG and corporate sustainability. Therefore, Siemens provides the visualization of carbon footprint, and through an open architecture, it provides customers with the ability to track the carbon footprint of their machines from the materials to the production. The goal is not only to achieve ESG by the company itself, but also to make it easier for customers to accomplish ESG responsibilities.

The whole solution to achieve this goal includes intelligent machine tools with networking capabilities, intelligent production lines with high productivity, and intelligent virtual machine tools with reduced environmental burdens, allowing more simulations and repairs before being put into manufacturing. The most special is that the ACM software system (Adaptive control and monitoring) can provide continuous tracking and optimization of machine tools and machine tool production lines.

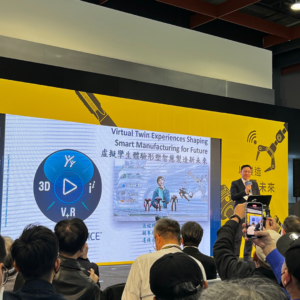

The sales Director introduce the practices of virtual twins. It not only simply describes the product, but also covers the entire product life cycle. Including the evaluation of real-world production application scenarios, and then simulating that the product can solve the user’s problem. So as to improve the user experience.

Dassault Systèmes’ 3D Experience Twin provides a design management platform with a manufacturing operation management platform. From the beginning of design, it can carry out 3D simulation design and digital information management to enter mass production assembly. In addition to manufacturing planning and scheduling optimization, it also can use VR/AR technologies to train operators, track production lines, and provide better quality control. At the same time, data are used to analyze carbon emission strategies to ensure that the entire production and supply chain are more competitive.

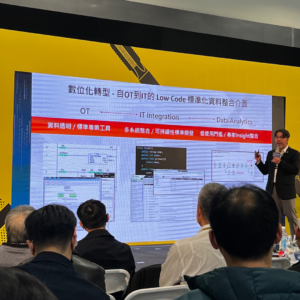

Taiwan's Rockwell

How Does Manufacturing Digitally Transform?

The senior consultant for the development of smart manufacturing applications discussed in detail the solutions to carbon emissions, and how to start evaluating carbon footprints from the moment an order is placed. At the OT layer, it is necessary to achieve information transparency and use standard professional tools. At the IT integration layer, it is necessary to achieve multi-system integration and sustainable standard development. At the same time, AR is introduced to assist experience inheritance, maintenance and inspection, and remote collaboration. It echoes the concepts of the previous speakers: when the information is visualized and the digital twin becomes effective. He also presented a case of remote maintenance through vision + AR/VR technology in a video.

The final round-table discussion addressed how companies can respond to future trends. Taiwan’s advantages lie in the integration of the international market and its top-notch ICT industry ecosystem. Another major feature of the machine tool industry here is the family business. The new generation brought new thinking and also accelerated digital transformation. As long as resources are properly used and the focus is on the niche market, even if it’s limited, Taiwan companies still can exert.

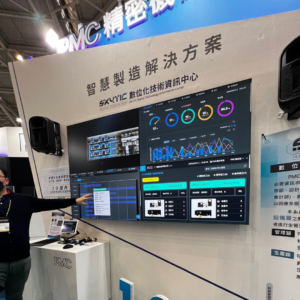

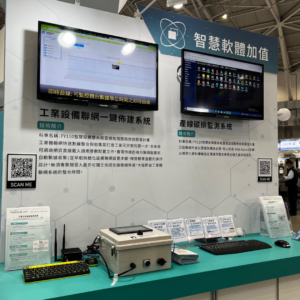

Metalworking Ecosystem Guided Tour

To seize the business opportunities of global supply chain reorganization and mechanical equipment upgrade, the “Metalworking Ecosystem Guided Tour” was launched by TIMTOS 2023. Netiotek joined the tour and walked into booths to explore the more comprehensive trends & knowledge of metalworking.

Share Our Insight With You !

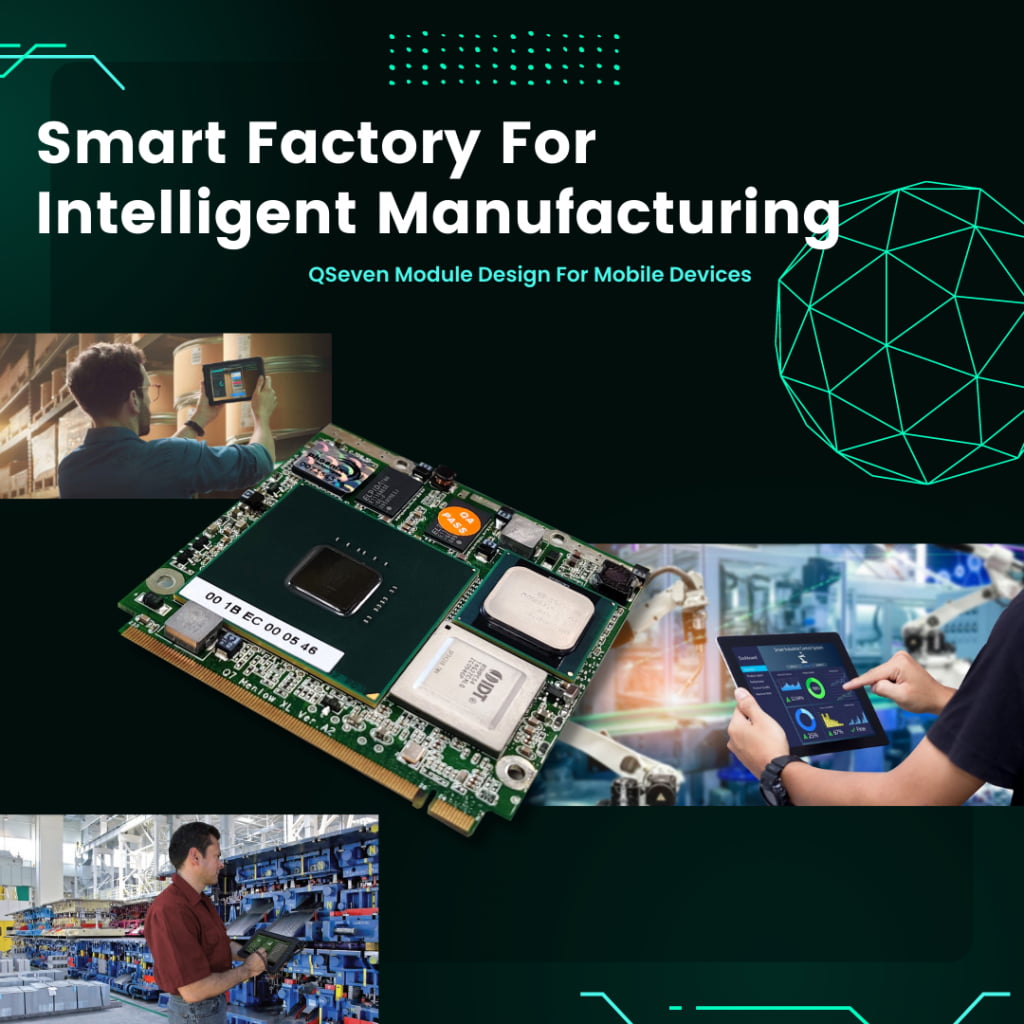

Smart Factory for intelligent Manufacturing- Part 1

Technological advancements brought innovations in several industrial fields.

Smart Factory for intelligent Manufacturing- Part 2

The fourth Industrial Revolution (Industry 4.0, aka IIoT, Industry Internet of Things) is here to stay.

Smart Factory for intelligent Manufacturing- Part 3

Previously in our series of Smart Factory for Intelligent Manufacturing, we elaborated Computer-on-Module (COM)....

Smart Factory for intelligent Manufacturing- Part 4

To deliver a solution for a variety of smart factory workloads, such as machine automation....

Want to know more about Intelligent Manufacturing ?

Subscribe! Automation News! Whitepaper!

Netio Technologies

Your Best Design Partner !