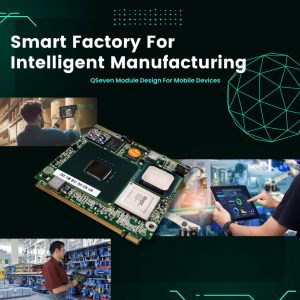

Smart Factory for intelligent Manufacturing- Part 2

Enhancing High-Performance Automation in an Interconnected World

In the realm of industrial automation, systems are taking on more tasks than ever before. These systems operate with greater speed, accuracy, and resilience, even in harsh and challenging environments. As we step into the era of the “Industrial Internet,” the demand for data grows exponentially. Machines are increasingly interconnected, spanning industries such as oil and gas, locomotives, transportation, and ship propulsion.

The Challenge: Data Demand and System Longevity

To keep pace with this data-driven landscape, industrial systems must perform faster and endure longer operational cycles. However, upgrading computer processors can be costly and time-consuming. Businesses face the dilemma of either replacing entire carrier boards or dealing with processor downtime. According to a 2006 Department of Energy study, idle industrial machinery can incur staggering costs—up to $800 per minute.

The Solution: COM Express Modular Architecture

Enter COM Express, a modular embedded computing architecture that tackles these challenges head-on.

Here’s why it stands out:

1.Computing Power: COM Express modules provide the necessary computing muscle for today’s interconnected world. Whether it’s real-time data processing or complex algorithms, these modules deliver.

2.Extended Lifespan: As chip technology evolves, users can seamlessly swap out COM Express modules without disrupting the underlying hardware. This longevity saves both time and money.

3.Modularity: COM Express embraces modularity, allowing businesses to adapt swiftly to changing requirements. Need an upgrade? Swap the module, not the entire system.

4.Simplicity and Reliability: The straightforward design of COM Express ensures reliability and ease of integration. Businesses can focus on staying competitive and profitable.

We have been using ADLINK COM Express Type 6 for Industrial Control applications and the features are below:

1.Provides 2.5 GbE Ethernet and 4 USB 3.2 Gen 2 ports, enabling high transfer rates.

2.Utilizes Intel Time Coordinated Computing (TCC) combined with Time-Sensitive Networking (TSN) Ethernet controller, making it suitable for Industry 4.0 factories.

3.Balances smart agility and autonomy with robustness and reliability

Smart Factory for intelligent Manufacturing- Part 5

In the previous article of our series, we introduced rackmount computers which can provide an organized working station or stable & high-performance systems.

Smart Factory for intelligent Manufacturing- Part 4

To deliver a solution for a variety of smart factory workloads, such as machine automation,

Smart Factory for intelligent Manufacturing- Part 3

Previously in our series of Smart Factory for Intelligent Manufacturing,

Smart Factory for intelligent Manufacturing- Part 1

Technological advancements brought innovations in several industrial fields.

Sign up for our email brief for IPC articles, news, and more.

Netio Technologies

Your Best Design Partner !