Smart Factory for intelligent Manufacturing- Part 5

In the previous article of our series, we introduced rackmount computers which can provide an organized working station or stable & high-performance systems. When it comes to computing in harsh environments, a rugged computer is the better fit then. Many manufacturing environments have extreme conditions: heat, dust, moisture, chemical exposure, cold vibration, etc. With the rise of edge computing and major benefits from 5G networks, edging computing helps to alleviate processing workloads. This is where a purpose-built rugged computer comes into place.

A rugged computer or ruggedized computer is a specialized computer. It is designed to operate reliably in harsh usage environments and conditions we mentioned before. Especially to deploy at the edge, the environmental conditions are the basic level qualification. However, besides specific use for the extreme scenarios, when a rugged PC needs to be also “thin” for limited space the design also faces thermal and power management.

Challenges for rugged computer design are:

1.Shock and vibration

2.Temperature and humidity

3.Corrosion and abrasion

4.Minimal size, weight, and power (SWaP)

5.Acoustic noise reduction

6.Low pressure/altitude

7.Ingress protection

8.Electromagnetic interference

To fulfill the requirements, the internal electronic components and chipsets are made to withstand that vibration and absorb shock over years of daily use, while the exterior and display are tough enough to function normally despite these conditions. Many rugged PCs also meet MIL-STD-810 Certified. MIL-STD-810 is a standard specifically for military applications and the standard’s guidance and test methods are intended to define the higher level of stress sequences, durations, and life cycles.

An example of a MIL-STD-810 Certified computer, Netiotek designed its ability to withstand higher and lower operating temperatures than typical commercial components. Design engineering decisions such as reduction of cabling, the addition of liquid cooling and heat sinks, and rugged materials, are made to ensure performance in harsh environments.

Features include fully sealed to protect against intrusion by dust or liquids. We also offer mobile solutions- tablets and laptops.

Stay tuned with us!

Smart Factory for intelligent Manufacturing- Part 6

Factory automation is the main development for Industry 4.0.

Smart Factory for intelligent Manufacturing- Part 4

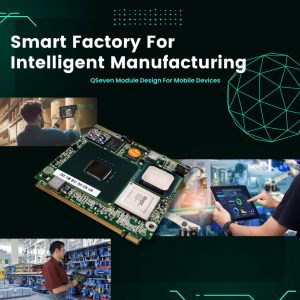

To deliver a solution for a variety of smart factory workloads, such as machine automation,

Smart Factory for intelligent Manufacturing- Part 3

Previously in our series of Smart Factory for Intelligent Manufacturing,

Smart Factory for intelligent Manufacturing- Part 2

The fourth Industrial Revolution (Industry 4.0, aka IIoT, Industry Internet of Things) is here to stay.

Sign up for our email brief for IPC articles, news, and more.

Netio Technologies

Your Best Design Partner !

Copyright © 2024 NETIO Technologies | Powered by NETIO Technologies