Taipei International Machine Tool Show (TIMTOS)

Topic 3: Smart Manufacturing

Smart manufacturing is the policy direction of industrial upgrading vigorously promoted by various advanced industrial countries in recent years. Skilled labor, a more highly connected and responsive industrial supply chain. For the machine tool industry, the importance of smart manufacturing is not to be underestimated. This year, the organizer also took smart manufacturing as one of the tour themes, planning four routes to guide the audience from cutting-edge manufacturing, precision processing, multi-processing and the National Pavilion. Cut in at all levels to understand how machine tools coexist with smart manufacturing, transformation and development status.

NEURELLI is good at using AI artificial intelligence, through data analysis, to establish artificial intelligence prediction system for customers, to achieve the goal of improving efficiency, yield and accuracy. The main services include: punch press safety protection, intelligent manufacturing system (Master 4.0) and license plate recognition.

The “Punch Press Safety Protection AI Solution” displayed on the spot is a new factory safety warning system. The industrial AI cameras installed on the production line can quickly detect and identify human limbs and objects in the set dangerous area, and send out warnings in advance. In a dangerous state, the operation of the machine tool can be stopped immediately to prevent personal injury.

Road Ahead Technologies enjoys a high reputation in the field of 3D measurement and 3D printing. It provides complete solutions from product development and design to manufacturing. The services include reverse engineering, CAV inspection, 3D printing, metal printing and laser embossing engineering service.

According to the on-site personnel, because 3D printing does not need to develop molds, can be rapidly prototyping, has a wide range of applications, and is suitable for composite materials other than metals, it is especially suitable for small-volume proofing and manufacturing special-shaped objects.

Taiwan Takizawa has inherited the machine tool manufacturing technology of Japan’s Takizawa Iron Works, and has rich experience in precision machining. Its main products include CNC lathes, PCB drilling machines, and vertical large lathes. Taiwan Takizawa, which has been through half a century, has been committed to research and development of manufacturing technologies that reduce energy consumption, and launched a “green smart machine” solution at this year’s exhibition, featuring three major features: high precision, high efficiency, and low energy consumption.

At the same time, a variety of smart new machines were also exhibited, all of which are equipped with intelligent software developed by Taiwan Takizawa itself, including energy monitoring, processing optimization, processing monitoring, friendly operation interface and remote maintenance, etc.

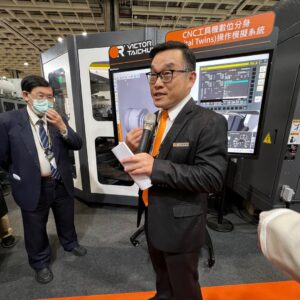

Victor Taichung Machinery Works has been deeply involved in Taiwan for more than half a century, providing services covering CNC lathes, comprehensive processing machines, plastic injection molding machines, precision casting, precision machining, sheet metal manufacturing, etc.

In today’s era of smart manufacturing, Taichung Precision Machinery promises itself to become “Taiwan’s professional manufacturer of smart machinery” and “the best integrated manufacturer of industrial 4.0”. In this exhibition, Victor Taichung Machinery Works takes the three Gs (Green Factory, Green Machine, Green Goal) as the main perspective, and showcases the global operation headquarters and smart chemical factory located in the Taichung Precision Park (which has won the green building label certification), and the high-level smart and energy-saving Machine tools and automatic production lines, as well as CNC digital twin processing simulation systems and other related technology applications.

JAINNHER has 40 years of experience in the field of grinding machines. It is a professional manufacturer of precision grinding machines in Taiwan. It has a complete series of grinding machines, covering traditional manual to NC / CNC models. The self-developed grinding machine combined with measuring instruments can avoid the occurrence of wrong workpiece placement, and at the same time protect the safety of machines and personnel.

EASUN has 40 years of experience in the field of grinding machines. It is a professional manufacturer of precision grinding machines in Taiwan. It has a complete series of grinding machines, covering traditional manual to NC / CNC models. The self-developed grinding machine combined with measuring instruments can avoid the occurrence of wrong workpiece placement, and at the same time protect the safety of machines and personnel.

Note: Non-cutting time refers to the time when the machine is in operation but not in actual production, such as tool positioning, moving, tool changing and other necessary procedures.

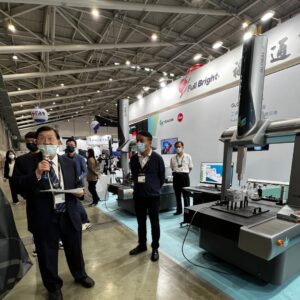

FULL BRIGHT (Swiss Pavilion) is a professional agent of European and American precision machine tools and precision measuring instruments. From machine installation to education and training, and after-sales service, there are qualified engineers trained in the original factory to provide professional services. The main agents of imported brands include TESA, HEXAGON, DANOBAT, DANOBAT-OVERBECK, etc. The items include three-dimensional coordinate measuring instruments, various precision measuring tools, high-precision projectors, 3D solid microscopes, optical trackers, and mobile large-stroke measurement instrument and so on.

GRUNDFOS (Denmark Pavilion) is a well-known brand from Denmark in Northern Europe. It provides a full range of intelligent pumps, motors, drivers, sensors and control devices. It is a leading brand in the world’s advanced pump solutions and water resources technology. According to Grundfos, up to 35% of the energy consumed by a machine tool during operation comes directly from the pump. In this regard, the iSolutions intelligent solution launched by Grundfos in this exhibition has made remarkable achievements in reducing energy consumption, helping the cold cutting system of Volkswagen’s Braunschweig workshop in Germany to reduce energy consumption by 37%.