Automated Optical Inspection

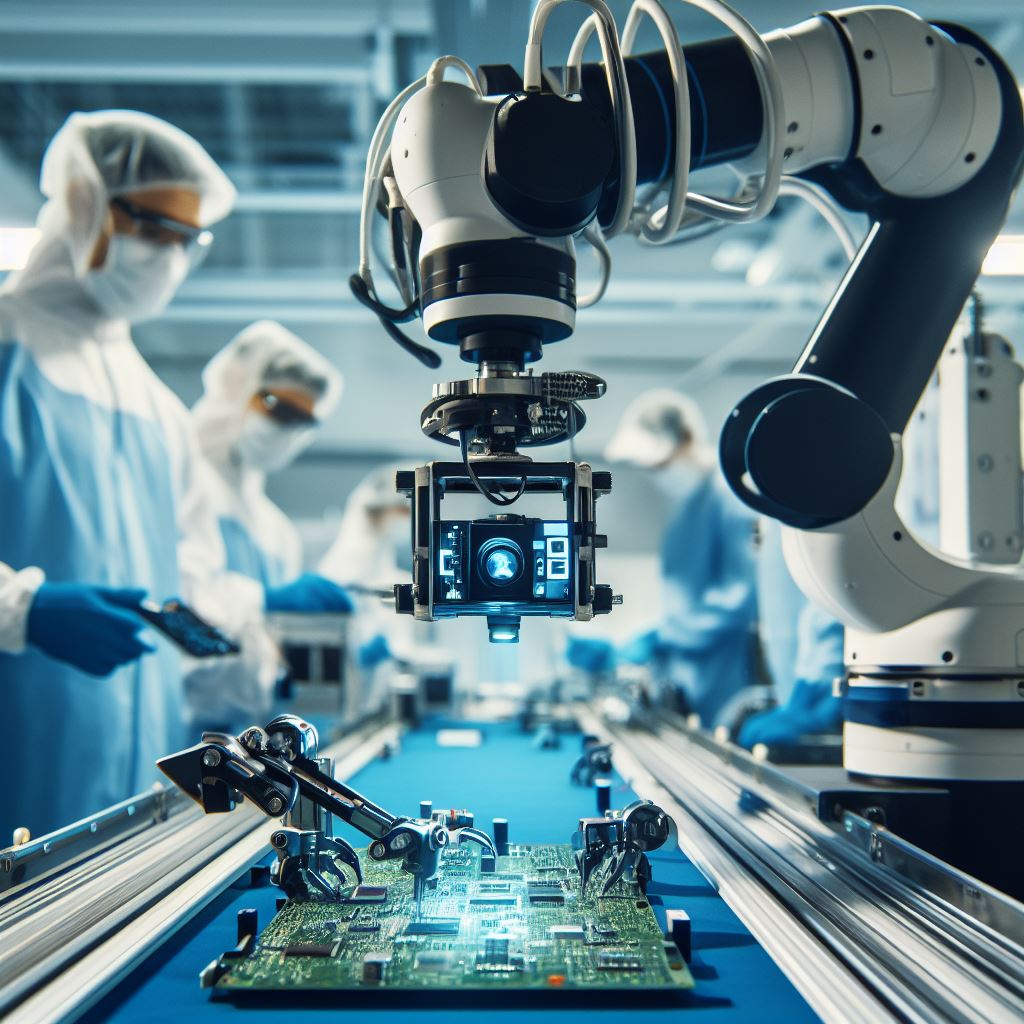

AOI stands for Automated Optical Inspection, which is an automatic visual inspection technology used for detecting defects and quality issues. It uses a camera to automatically scan the object being tested and detect whether there are catastrophic faults or quality defects. It is a non-contact inspection method that can replace manual visual inspection, improving the accuracy and efficiency of inspection.

AOI systems typically include multiple light sources and multiple cameras, sometimes including video cameras. The light sources illuminate the object being inspected from different angles, and the cameras take pictures or videos to create a comprehensive image for evaluation. AOI systems can perform inspections at multiple stages of the production process.

As technology has advanced, it has completely changed the way manufacturers operate. Manufacturers always invest a lot of effort in finding ways to improve production efficiency. The introduction of automatic optical inspection combined with production management systems has become a mature solution for effectively improving production efficiency and accuracy.

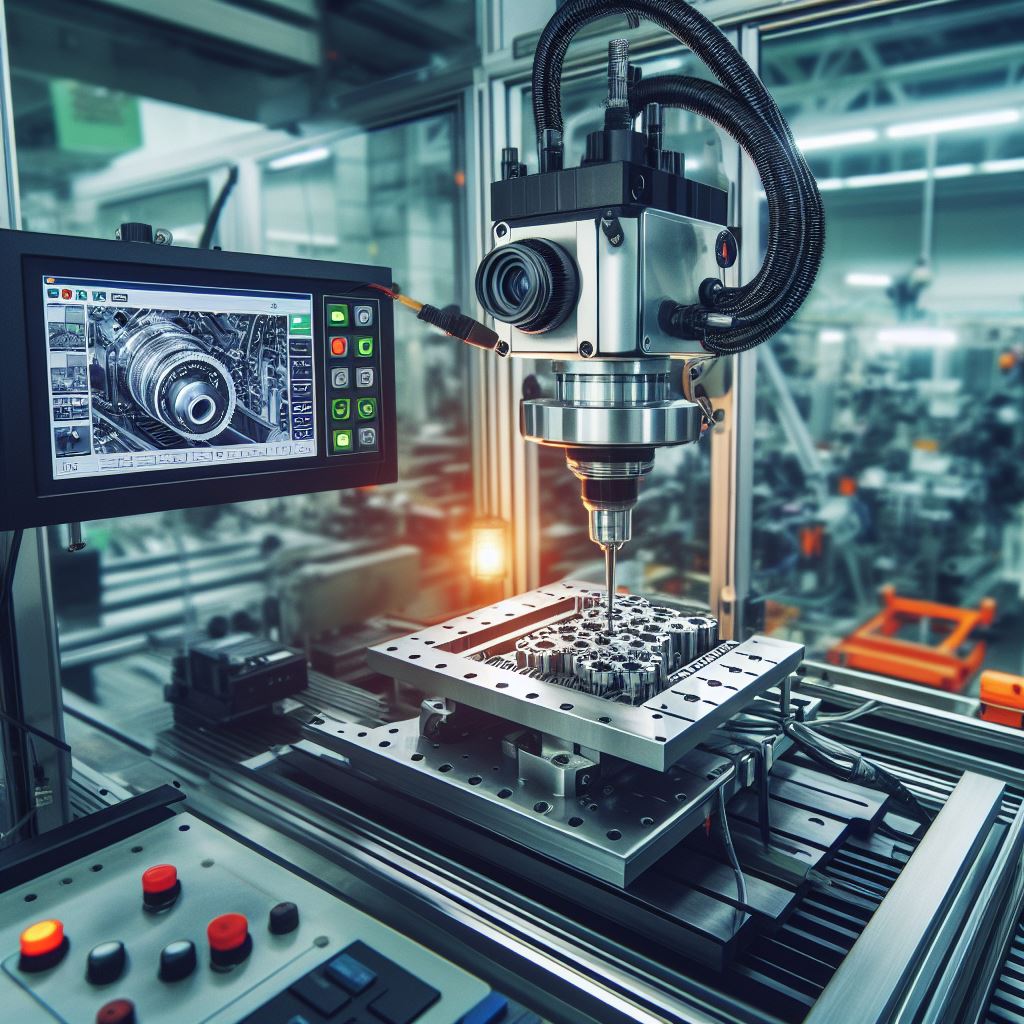

For example, metalworking machinery manufacturers use metalworking equipment to complete their work. These devices use various forces such as manual, pneumatic, hydraulic, and servo-electric to bend and punch metal. These devices are common in sheet metal and other industries, ranging from small devices that can be placed on a workbench to room-sized devices.

Until recently, the defect detection process for products produced by stamping machines mainly relied on manual inspection. People needed to pick up the metal plate and flip it multiple times for visual inspection. This method is not only inefficient, but also difficult to ensure accuracy due to the reflectivity of metal, different surface properties, and various pressure molds used.

Therefore, manufacturers have been committed to eliminating manual defect inspection from the stamping machine production line in recent years.

Compared with human inspectors, Automated Optical Inspection (AOI) systems can significantly improve production efficiency and accuracy, and reduce the operating costs of defect detection. In addition, these advanced manufacturing solutions can also be integrated with machine monitoring solutions (production management system software, PMS), allowing factory operators to visualize, manage, and process process data from dozens or even thousands of stamping machines in real time.

Although AOI systems are not new, they have developed to the point where they can detect previously difficult-to-detect defective components. The importance of improving production efficiency and accuracy has already taken root in the production line. The next step of progress will depend on breakthroughs in artificial intelligence and visual technology.

Next, we will introduce the detailed specifications of AOI-related applications, and we will also delve into AI-based AOI: more than meets the eye.

Visit our AOI Solution Partner

Netio Technologies

Your Best Design Partner !